What is 3-axis Machining?

- SA JBM

- Oct 5, 2022

- 2 min read

Updated: Oct 17, 2022

Three-axis machining is regarded as the simplest form of CNC milling, but that doesn’t mean that it is simple in and of itself. Follow along as we break down this standard type of machining.

First, it’s important to understand what milling is. Milling is using a quickly spinning cutting tool to cut away stock material. It is essentially carving away metal – and sometimes wood or plastic – to “reveal” the tool underneath. If you want more information, Modern Machine Shop gives a thorough explanation of milling and different axes in A New Milling 101: What Milling Is, Then and Now (Plus a Glossary of Milling Terms). Three-axis machining is a style of milling that allows the tool – or spindle – to move in three linear directions: the X-, Y-, and Z-axes. These directions are up and down, left and right, and back and forth.

What are the differences between 3-axis machining and 4- and 5-axis machining?

While 3-axis machining uses the X-, Y-, and Z-axes, 4- and 5-axis machining rely on one or two more axes, respectively. There are innumerable 4th and 5th axis machining center configurations, but they all use rotary axes in addition to the linear axes.

For example, a 4-axis machine will use the standard X-,Y-, and Z-axes, but it may use an additional A-axis. This A-axis spins around the Z-axis. It uses this additional rotational axis by rotating the workpiece. Therefore, 4- and 5-axis machining centers are defined by their ability to use the additional rotary axes.

What are the applications of 3-axis machining?

Even as multiaxis machining becomes more and more pervasive, 3-axis continues to hold its ground as a useful practice. 3-axis machining is perfect for parts that only need one or two sides to be cut, and therefore would only need one or two setups. These parts are often the simple ones with just milled profiles, drilled planes, and/or threaded holes. Shops that don’t want to get into multiaxis for whatever reason find that 3-axis machining is a simple, economical solution for simple part manufacturing.

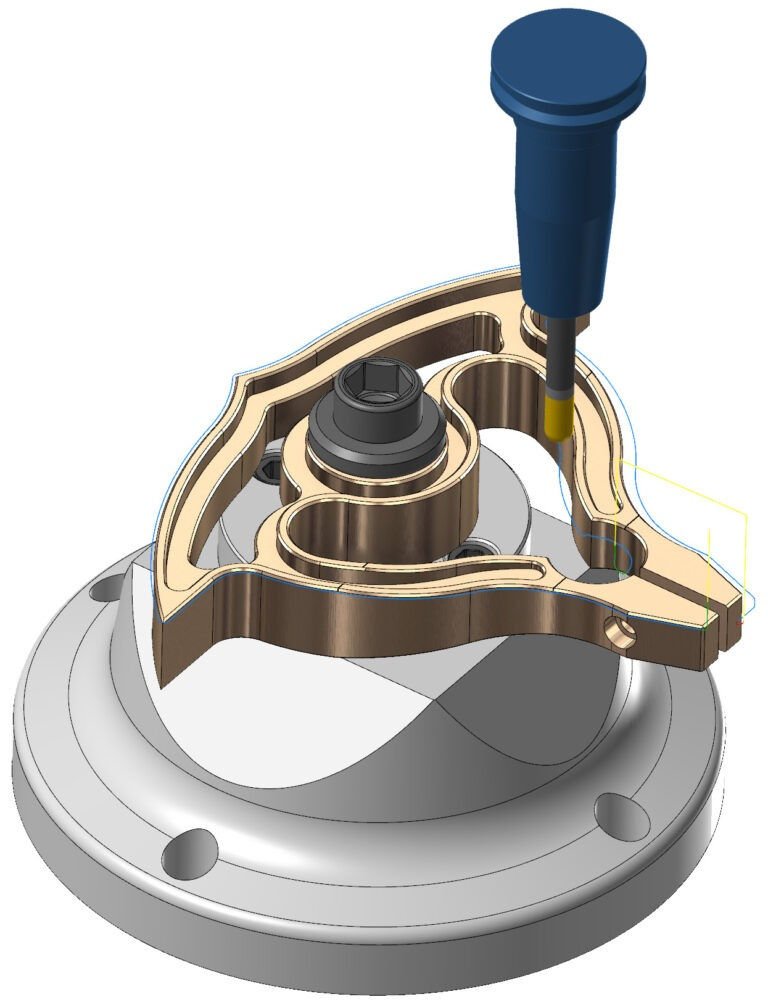

Mastercam Mill for 3-axis machining

Mastercam Mill is a product specifically designed to equip machinists with the most powerful and efficient 3-axis toolpaths available. The package includes solid, wireframe, and surface functionality, and the standard CAD tools and simulation features make add-on products unnecessary for the vast majority of parts. For those interested in multiaxis cutting, 3+2 machining comes with all Mastercam Mill seats and is a stepping stone towards true multiaxis machining.

Try it yourself

Ready to give it a go? Visit Mastercam Learning Edition to download your free software demo.

Comments